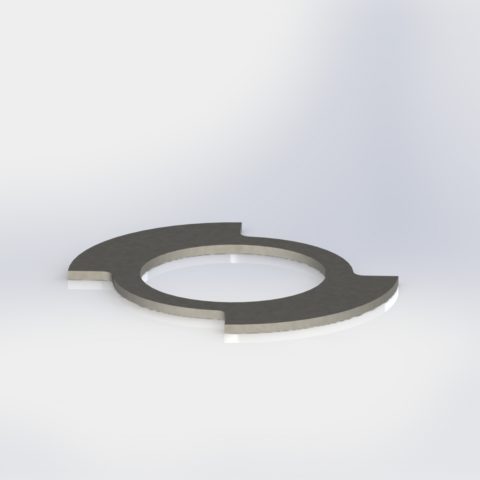

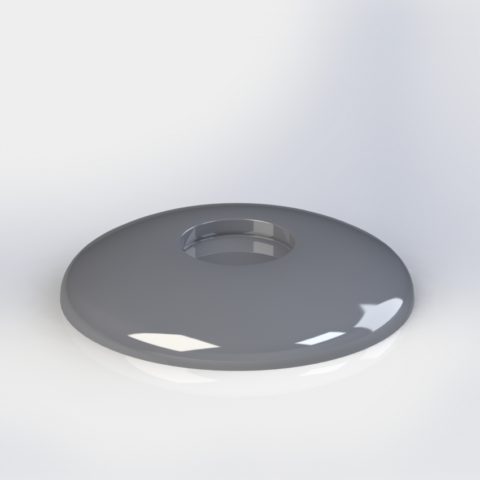

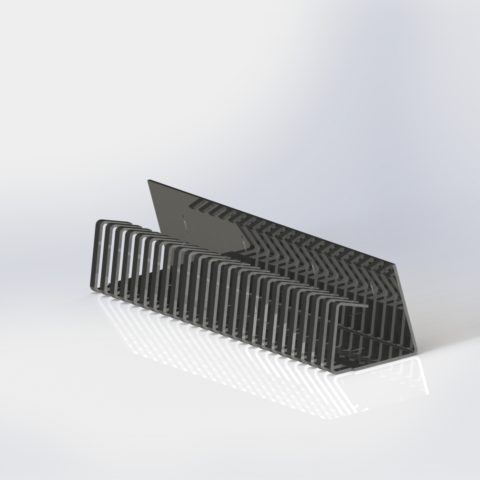

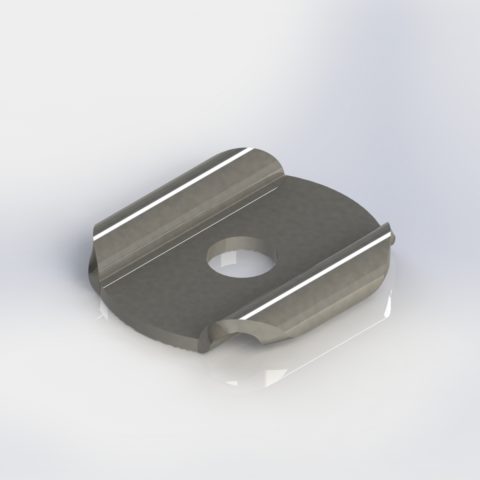

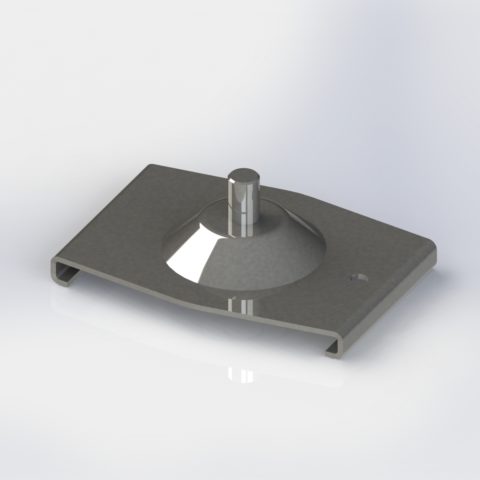

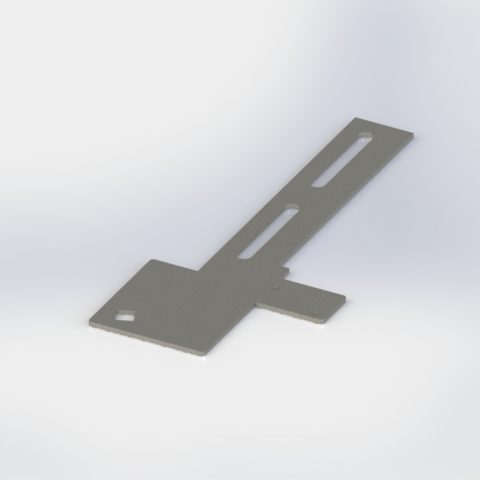

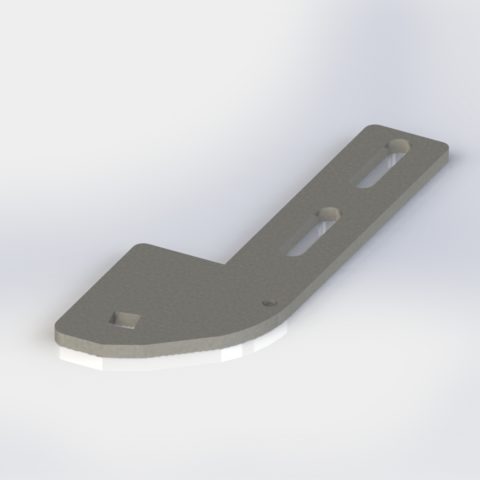

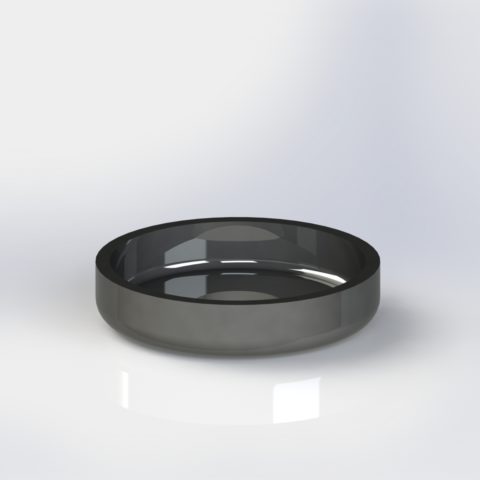

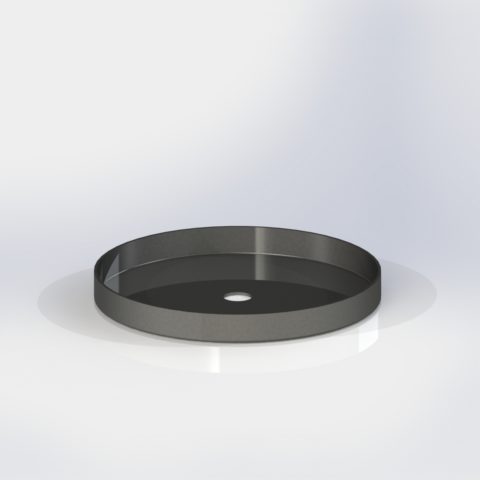

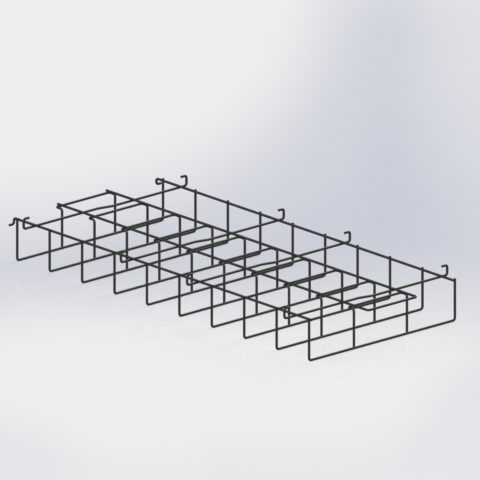

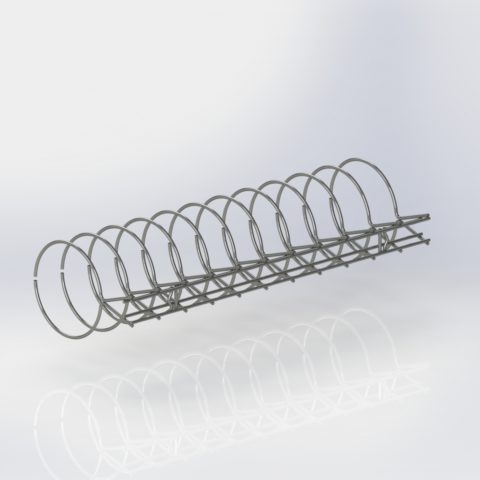

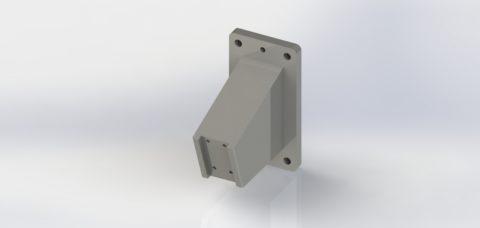

Descrizione del prodotto

Sheet metal stamping or cold forming is used where the traditional carpentry part reaches such a volume that it is necessary to industrialize the production process by avoiding several machine tool passes.

Thicknesses up to a maximum of ≤6mm are intended.

To make the part, it is necessary to produce a mold to obtain the shape.

These are normally irregularly shaped, deep-drawn parts with holes and deformations on the planes.